The Evolution of Industrial Fastening Solutions

Fastening technologies have come a long way from the rudimentary methods like nails and screws to more sophisticated solutions such as industrial-grade adhesives and mechanical fasteners. The emergence of Velcro has significantly altered the landscape, initially finding use in consumer goods before migrating to high-stakes industrial environments.

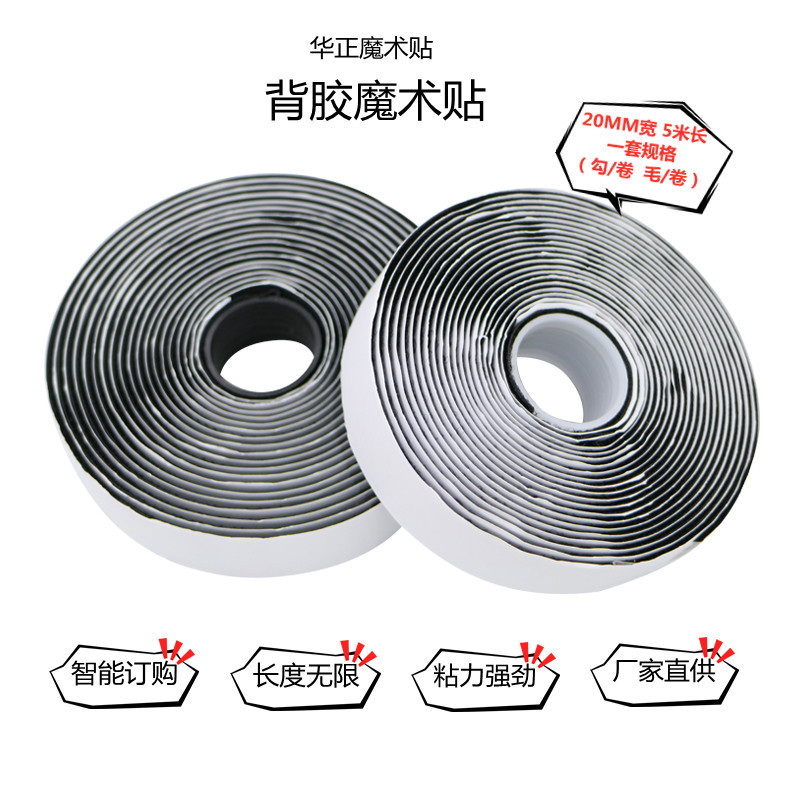

Characteristics of High-Tack Double-Sided Adhesive Velcro

High-tack double-sided adhesive Velcro combines the convenience of traditional hook-and-loop fasteners with an added layer of durability through its enhanced adhesive backing. This material is known for its waterproof properties, strong viscosity, and excellent adhesion resistance, making it a reliable solution across various applications. Compared to other fastening options like bolts and tapes, high-tack Velcro offers seamless installation and repositioning capabilities, reducing downtime during maintenance or assembly tasks.

Diverse Applications in Various Industries

Manufacturing

In manufacturing settings, high-tack adhesive Velcro greatly enhances assembly line efficiency. It assists in securing components during production, ensuring that they remain stable without permanent fixtures until final assembly, thereby streamlining workflow processes.

Automotive

The automotive industry benefits immensely, using this robust fastening technology for attaching interior panels securely. Additionally, it proves invaluable in managing loose wires and cables, offering a neat and effective solution for organizing critical electrical components.

Aerospace

Lightweight yet strong, high-tack adhesive Velcro is increasingly applied in aerospace engineering. Its application ranges from holding spacecraft components in place to providing easy-to-handle yet secure fastening options for different equipment inside space vehicles, contributing to both safety and efficiency.

Case Studies

Electronics Manufacturing

The challenge of maintaining circuit board placement during assembly was effectively addressed by implementing high-tack Velcro for stability. This led to increased production speed and reduced errors, demonstrating clear operational benefits.

Construction

Difficulty in attaching insulation materials within tight spaces often disrupts construction timelines. By utilizing double-sided adhesive Velcro, workers can achieve quicker installations, improve insulation performance, and substantially reduce labor costs.

Medical Devices

Securing components in medical devices without resorting to permanent fixtures can be challenging. High-tack Velcro allows for easy attachment and detachment, enhancing device functionality while also simplifying maintenance routines.

Maintenance and Durability Considerations

High-tack adhesive Velcro promises longevity even when exposed to harsh environments. To ensure optimal performance, surfaces must be prepared adequately before application. Environmental factors like temperature and surface cleanliness play significant roles in influencing adhesive effectiveness.

Innovations and Future Trends

Recent advancements in adhesive technology continue to push boundaries, increasing the potential uses of high-tack Velcro in emerging industries. Sustainable and eco-friendly alternatives are also being explored to align with the global shift towards environmentally responsible practices.

Expert Tips for Implementation

Selecting the right type of high-tack Velcro involves considering specific application needs. Proper surface preparation and following detailed application techniques will ensure long-lasting results. Avoid common pitfalls such as applying on uneven or dirty surfaces to maximize adhesive strength and durability.

Feedback from Industry Professionals

"We've seen remarkable efficiencies in our assembly lines after integrating high-tack double-sided adhesive Velcro. It's not only saved us time but also reduced error rates significantly," said John Smith, a senior engineer at Tech Innovations Inc.

"Using high-tack Velcro has transformed how we manage internal panel setups in our car models. It's quick, efficient, and durable," noted Jane Doe, an automotive technician at AutoWorks Ltd.

Conclusion: The Impact on Industrial Efficiency

High-tack double-sided adhesive Velcro is revolutionizing fastening solutions across multiple sectors. From improving production speeds in electronics manufacturing to enhancing insulation performance in construction, its benefits are far-reaching. With continued innovation and sustainability efforts, it's poised to set new standards in industrial efficiency and reliability. Engineers and technicians should consider adopting these advanced fastening solutions to optimize their workflows and enhance product quality.