The Power of Self-Adhesive Velcro in Industrial Settings

Self-adhesive Velcro technology has revolutionized fastening methods across various industries. This ingenious invention, featuring a strong adhesive backing combined with the versatile hook-and-loop system, allows for quick and efficient attachment and detachment of materials. Originating from George de Mestral's initial Velcro patent in 1955, self-adhesive Velcro has evolved to meet industrial demands, providing robust solutions where traditional fasteners fall short.

Unmatched Bonding Strength

In comparing double-sided adhesive Velcro to conventional fastening methods like screws or bolts, the strength of Velcro in demanding environments becomes evident. For example, heavy tools and equipment can be securely attached without risk of slippage, even under significant stress. The high-quality adhesive offers reliable performance on surfaces such as plastic, stainless steel, and painted walls, making it indispensable in situations requiring strong, dependable bonds.

Versatility Across Various Industries

Self-adhesive Velcro showcases its versatility through widespread use in multiple sectors. In manufacturing, it's used for both temporary fixes and permanent solutions, enhancing efficiency and reducing downtime. Construction sites leverage Velcro to secure tools and materials quickly. The automotive industry benefits from effective cable management and seamless panel attachment, while aerospace applications rely on Velcro's lightweight yet durable properties for fastening sensitive components.

Ease of Use and Time Efficiency

Simplifying installation processes is another standout feature of self-adhesive Velcro. Unlike labor-intensive traditional fasteners, Velcro significantly reduces the time required for setup and tear-down. Case studies have demonstrated marked decreases in operational downtime, leading to increased productivity. Additionally, the application and removal process is user-friendly, allowing for adjustments without damaging the underlying surface or material.

Durability and Longevity

Industrial conditions often expose materials to harsh environmental factors like moisture, extreme temperatures, and chemicals. Self-adhesive Velcro is designed to withstand these challenges, maintaining its bonding strength over time. The longevity of its adhesive properties ensures that once applied, it can endure repeated use without failing. Easy maintenance and reusability further extend its lifespan, offering cost-effective long-term solutions.

Safety and Reliability

Enhanced safety is a crucial concern in hazardous environments. Self-adhesive Velcro provides secure attachments, minimizing the risk of accidents caused by slipping or falling objects. Its proven reliability in high-stress applications means that critical components remain firmly in place, meeting stringent industry safety standards and ensuring optimal operation.

Cost-Effectiveness

While the initial investment in high-quality self-adhesive Velcro may appear higher than some traditional fasteners, the long-term savings are substantial. Reduced need for additional tools, accessories, and maintenance translates into lower overall costs. Real-world examples highlight how businesses have cut expenses and improved bottom-line results through efficient use of Velcro solutions.

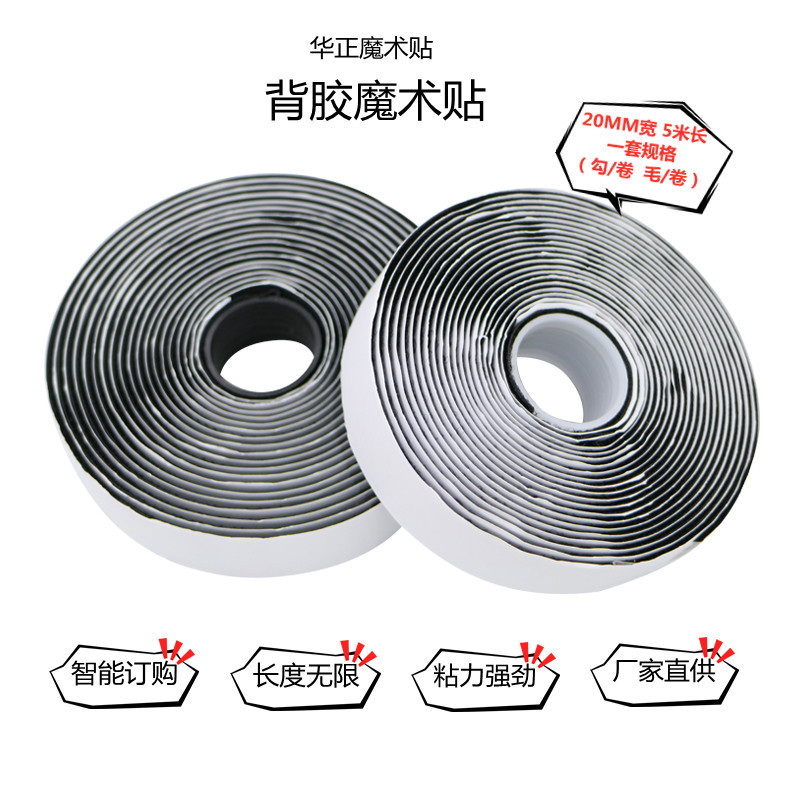

Customizability and Adaptability

The adaptability of self-adhesive Velcro makes it suitable for diverse project needs. Tailoring Velcro to specific requirements—whether custom sizes, shapes, or varying adhesive strengths—ensures an ideal fit for unique industrial applications. This flexibility allows businesses to address particular challenges effectively, optimizing operations and achieving desired outcomes.

Sustainability and Environmental Impact

Eco-conscious companies value sustainable industrial practices, and self-adhesive Velcro contributes positively in this aspect. Many options include eco-friendly adhesives and recyclable materials, promoting reduced waste. With reusable fastening solutions, industries not only benefit economically but also support broader environmental goals.

Future Trends and Innovations

The landscape of self-adhesive Velcro continues to evolve with emerging technologies and innovations. Future advancements promise enhanced adhesive formulations and designs, potentially expanding applications even further. Industry experts anticipate significant growth and diversification in the use of Velcro, keeping pace with technological progress and changing market demands.

Practical Tips for Implementation

When integrating self-adhesive Velcro into your operations, choosing the right type is paramount. Consider the specific requirements of your application, including the surface material and exposure conditions. Adhering to best practices during installation will ensure optimal performance, while troubleshooting any issues early on prevents future complications.

Real-World Success Stories

Numerous industries have successfully implemented self-adhesive Velcro solutions to great effect. Detailed case studies reveal insights gained from real-world applications, highlighting increased efficiency, safety improvements, and cost savings. Interviews with industry professionals provide valuable testimonials, showcasing the practical benefits observed firsthand. Visual examples offer concrete illustrations of successful projects.