In the world of fastening solutions, nylon Velcro stands out as a versatile and reliable option for countless applications. Understanding why quality matters in this seemingly simple product involves diving deep into its historical context, key quality indicators, manufacturing processes, testing protocols, diverse applications, and future trends. This detailed examination highlights why manufacturers’ commitment to excellence is critical for both industrial and everyday uses of nylon Velcro.

The story of Velcro begins with Swiss engineer George de Mestral's invention in the 1940s. Inspired by the burrs that clung to his clothes during a walk in the woods, Mestral mimicked nature’s hook-and-loop system in what would become known as Velcro. Fast forward to today, and we see an evolution where nylon has been introduced to enhance the performance and durability of this ingenious fastening material. The addition of nylon has not only improved strength but also broadened its application across various industries.

When discussing the quality of nylon Velcro, several key indicators come into play:

Strength and Durability: High-quality nylon Velcro showcases exceptional tensile strength, which means it can withstand significant stress without breaking. Wear and tear resistance are essential for products used in demanding environments, ensuring longevity and reliability even after multiple cycles of use.

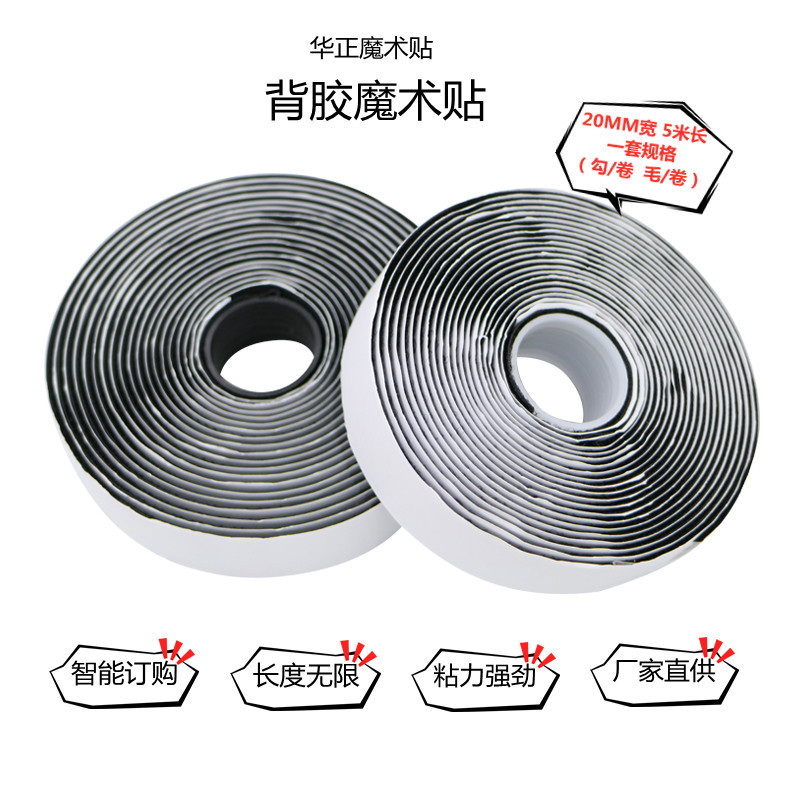

Adhesive Performance: Different adhesives are applied to nylon Velcro depending on the intended application. For example, strong self-adhesive varieties offer prolonged efficacy, maintaining their stickiness over time and adverse conditions, adding another layer of dependability to the material.

Consistency in Production: Maintaining batch consistency through rigorous quality control measures ensures that every piece of Velcro meets stringent standards. Reliable suppliers implement advanced inspection technologies to detect any deviations in production, thus guaranteeing uniformity in their products.

The journey from raw materials to finished nylon Velcro involves numerous meticulous steps:

Raw Material Selection: The starting point is high-quality nylon, renowned for its combination of toughness and flexibility. Ethical sourcing and sustainability considerations are increasingly vital as manufacturers strive to minimize their environmental impact while maintaining superior material standards.

Weaving and Loop Formation: State-of-the-art machinery and precise techniques ensure optimal hook and loop creation. These methods create the perfect balance between hooks and loops, maximizing grip and minimizing failure rates.

Adhesive Application: The process of applying adhesives must be both thorough and uniform. Methods vary, but the goal remains constant: evenly distribute adhesive to provide consistent performance across all areas of the Velcro strip or patch.

No discussion of quality would be complete without examining testing and certification:

Industry Standards: Adherence to ISO and other relevant certifications assures customers of compliance with international benchmarks. Comparing against competitors helps firms maintain their market edge and promotes continuous improvement.

In-house Testing Protocols: Comprehensive tests measure stress, strain, and environmental resistance factors like heat and moisture. Such assessments confirm that the product can perform reliably under varied conditions.

Nylon Velcro’s versatility sees it employed in several critical sectors:

Medical Industry: From securing medical devices to being integrated into patient apparel, high-quality Velcro plays a crucial role in healthcare settings, emphasizing safety and ease of use.

Aerospace and Automotive: These high-stakes fields necessitate fastening solutions that combine rigidity with resilience, making dependable Velcro indispensable.

Everyday Consumer Products: Beyond industrial applications, quality Velcro enhances consumer goods such as clothing, footwear, accessories, and household items, proving that careful production benefits day-to-day life as well.

As consumers or procurement specialists, recognizing quality when purchasing nylon Velcro is paramount:

Identifying Reputable Manufacturers: Seek attributes such as transparency in sourcing, comprehensive customer reviews, and documented case studies demonstrating successful usage. Be wary of common pitfalls associated with low-quality options, like poor adhesion and inconsistent thickness.

Looking ahead, advancements in nylon Velcro technology promise exciting developments:

Smart Materials and Adaptive Velcro: Innovations could lead to 'smart' Velcro that adjusts its properties based on environmental cues or user needs, opening doors to new applications.

Environmental Impact: As sustainability becomes non-negotiable, biodegradable options are emerging alongside traditional variants, aligning with broader eco-friendly trends.

Market Trends: Increasing demand from evolving industries—such as wearable tech and smart homes—continues to drive research and development in nylon Velcro technology.

If you're considering buying nylon Velcro, here are some practical tips:

Questions to Ask Suppliers: Investigate aspects like quality control protocols, available warranties, and customer support mechanisms to gauge reliability.

Sample Testing: Always request samples before committing to bulk purchases. Conduct hands-on tests comparing tensile strength, adhesive longevity, and overall feel against competitor offerings.

Insights from industry leaders reveal best practices and success stories underlying quality nylon Velcro implementations:

Expert Opinions: Interviews with top manufacturers shed light on the intricate balance required in creating high-caliber Velcro.

Case Studies: Real-world examples illustrate how investing in premium Velcro results in tangible benefits, whether in aerospace engineering or children's apparel.

In conclusion, grasping the importance of quality in nylon Velcro transcends basic functionality. It influences everything from safety and performance to durability and environmental footprint. Encouraging informed decisions in selecting high-grade Velcro ensures better outcomes whether you’re outfitting a hospital ward, constructing aircraft interiors, or simply looking for reliable fasteners for everyday use. Choose wisely, choose quality.